TOOLING COST

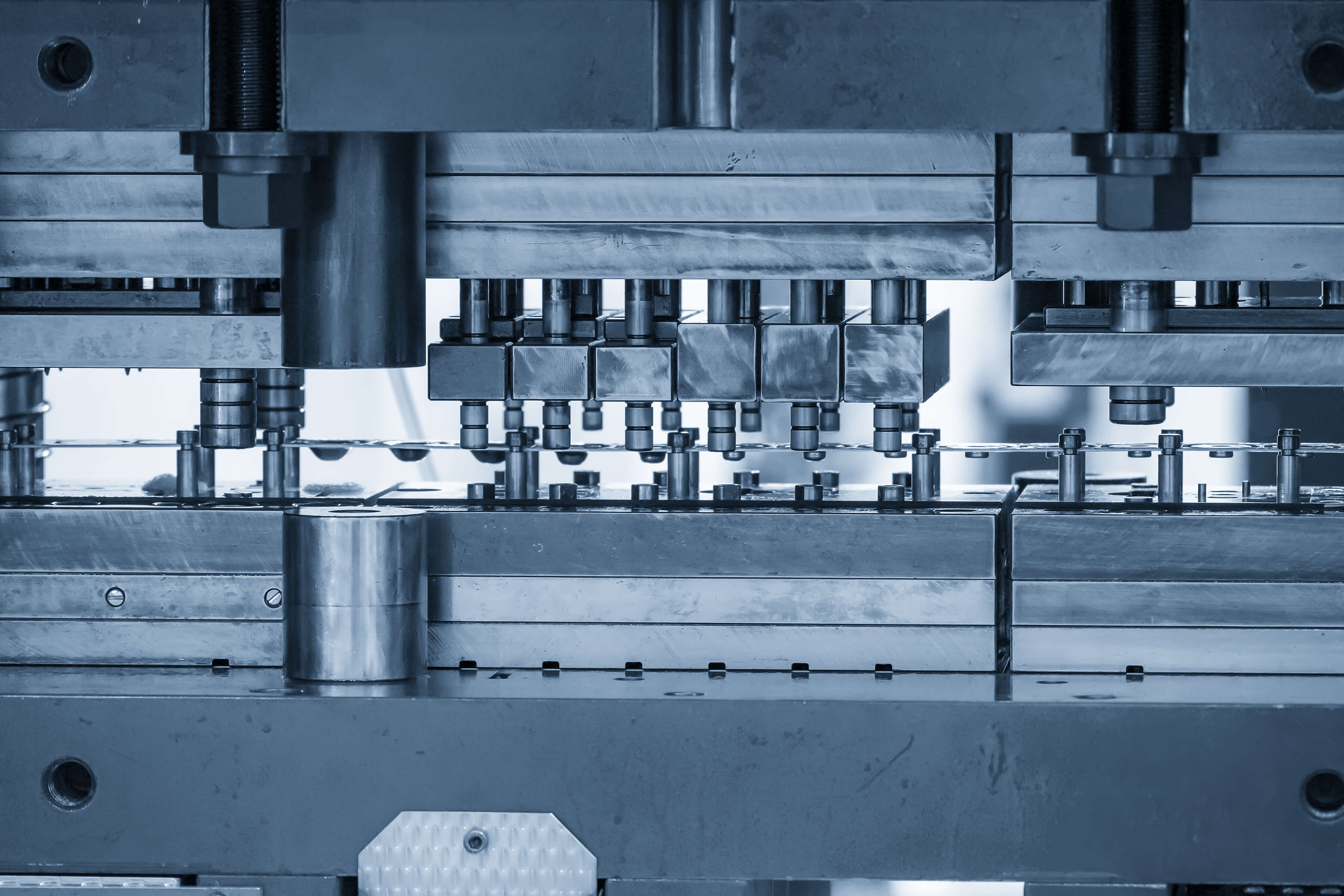

One of the most difficult issues we have as

mould manufacturers is competing in the worldwide market to create tooling at a low cost while

maintaining part quality. While most firms estimate tool prices based on experience or spreadsheets, they frequently make mistakes, either quoting too

high and losing the contract to the competition or incurring additional expenses later in the

production process, resulting in a financial loss.

It's tough for us to measure how much time and money we spend each month on mould quotation.

Other mould producers waste a significant amount of time and money each month quoting moulds

that will never be used. This business model will not work in the long term. Our single solution is a CAD software product that allows us to

precisely compute mould costs by recognising cost-drving geometric characteristics such as surface

area, volume, wall thickness, feature ribs, apertures, and undercuts..

The tool streamlines and automates the quotation process while removing reliance on third-party

apps. Machinability is assessed for 3D models created in or imported from CAD software, taking

into account the draught angle, wall thickness, mould flow, and plastic injection. Feature

recognition characteristics are then used to identify costing parameters. Then there's product

cost management, which we figure out for tooling cost estimation, as well as labour cost estimation, using our costing criteria.

CAD Advanced feature recognition also aids in the identification of characteristics that are

important cost drivers for product and mould costing estimation, as well as those that are necessary for cost models. 3D models provide an enterprise-wide platform for managing

calculations, as well as the foundation for standardised costing estimation, fact-based calculations, and cost transparency. We can provide rapid,

accurate cost estimates for quotations and tool cost analysis using calculations. Injection

moulding calculation, cost estimation, and cost with respect to production cycle are all part

of our product cost management.

Geometric parameters and features can be manually inserted into the geometry object, or CAD

software can be used to populate the geometrical parameters and features in a semi-automated

manner. While features are recognised automatically, it is always necessary to evaluate the

findings and interact with the data manually.

Advanced elements like as ribs, undercuts, bending regions, and so on are also detected by the

programme, which are necessary for calculating mould costs estimation, especially in the early

stages when no mould design is provided. We use this information to provide rapid and accurate

estimation after we've identified all of the cost factors.